allen bradley motor starter overload chart

Electric motors are the backbone of modern automation. More on the hardware modules later.

Allen Bradley 702 Coh93 Size 2 Contactor Motor Starter 208 Vac Coil 17d Ebay

We strongly recommend using a certified electrician.

. The Start and Stop switches the OL overload contacts and the M relay are hardwired to hardware modules that are part of the PLC. Motors convert electrical energy into mechanical energy and the resulting motion and torque drives a load. Your company may need to replace the wiring and other components.

Ultimately the faults cause will have to be remedied before it can be reset and the drive can start. Drives vary motor input frequency and voltage to control motor speed and torque. Finally a Port signal can indicate a loose connection to the port.

Siemens-Furnas Overload Relay Heater Tables For Irrigation Pump Panels. Kempston Controls - Electrical and Electronic Components Distributor. One way to prevent disconnected wiring is to keep your companys Allen-Bradley PowerFlex away from vibrations.

If a load loss is a problem check the wiring connection between the load and the motor. Allen Bradley Heater Tables. Interestingly many of the original physical devices are connected to the PLC.

The most effective motor control solution is the variable frequency drive or adjustable speed drive. Tips for Troubleshooting and Fixing Allen-Bradley Fault Codes. To quickly and efficiently troubleshoot a fault.

The VFDs showed in the video are the D720S 230V single phase and the D720 230V three phase. Kempston Controls located in the centre of the UK is a leading distributor of electrical process control and automation products and electronic components with a world-leading reputation for stock service competitive pricing and next-day delivery. Westinghouse A200 Overload Relay Heater Elements for Motor Protection.

Learn the basic wiring of variable frequency drives VFD with our electrician Steve Quist. In this video we used the very popular Mitsubishi D700 series VFD showing single phase and three phase wiring instructions. It may require a motor or drive repair.

In industrial applications today much of the Motor Starter circuitry is replaced by a PLC.

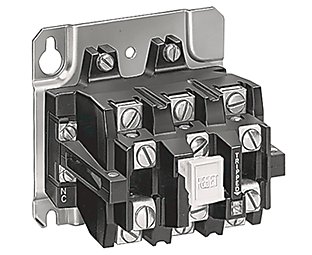

E300 Electronic Overload Relay How To Assemble A Nema Starter And E300 Youtube

Allen Bradley 505 Nema Full Voltage Reversing Starter Size 1 Open 115 120v 60hz With Eutectic Alloy Overload Relay State Electric

Iec Open Starters Allen Bradley

The Most Common Lv Mv Motor Starting Devices Eep

Nema Manual Motor Low Voltage Starters Allen Bradley

Iec Combination Starters Allen Bradley

8536sbo2 Square D Motor Starter

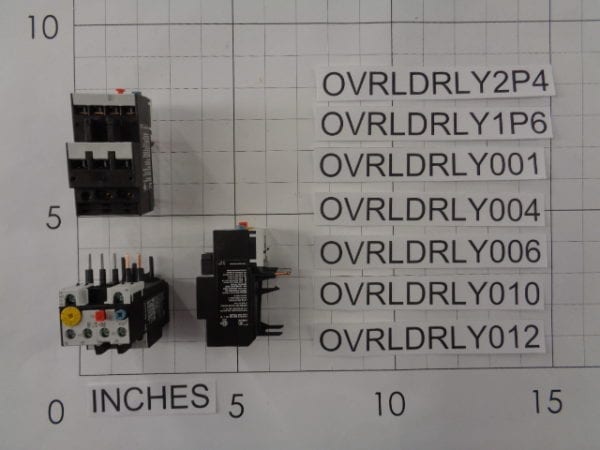

Motor Starter Overload Relay Ovrldrly004 Grieve

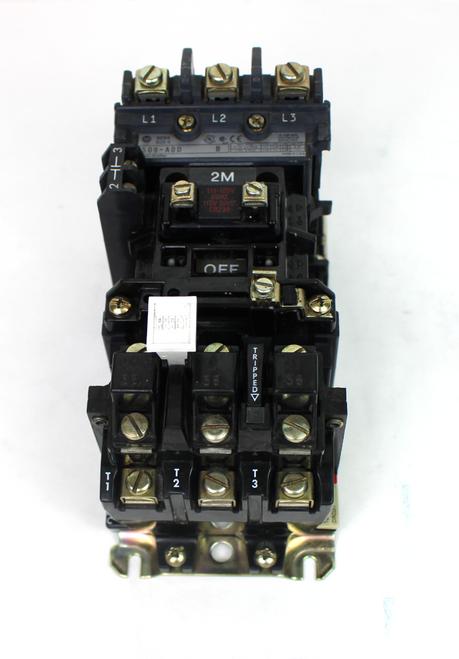

509dod Allen Bradley Motor Starter

03 0148 Motor Starter Size 2 Ab Waste Handling Machines Recycling Equipment L J B Equipment Co Inc

Allen Bradley E100 193 1eedb 1 3 Phase Basic Electronic Iec Overload Relay 3 2 To 16 A 690 Vac Coil Smc Electric

Allen Bradley 100 M05nz 3 193 A1e1 Motor Starter 20a Overload Relay Assembly

Wiring Diagram Contactor How To Wire A For 3 Phase Throughout Allen Bradley Motor Control Electrical Circuit Diagram Circuit Diagram Electrical Wiring Diagram

Compactor Parts Contactors Motor Starters Overloads Impact

Cutler Hammer Motor Starter Wiring Diagram In Allen Bradley Control Diagrams On Contactor Symbol 715 Gi Dry Type Transformer Diagram Electrical Circuit Diagram

New Used Obsolete Allen Bradley Automation Controls Plc Hmi Motor Controls

Sizing Heater Elements For Motor Starters